Architectural Fabrication’s Project Management Process

Architectural Fabrication’s project management team oversees the planning and executing of our products that end up on the walls of each building we complete. They are an integral part of our End to End solution heading over the transition from Pre Construction all the way to project completion. The project management team is equipped with knowledge and resources to help your project be as successful as possible.

We have an in-depth operations process for how our project management team operates to make sure information is communicated clearly for all parties and details are obtained during the project’s life. With the following blog, we want to give you some insight into how to complete our project successfully and how our Project Managers and Assistant Project Managers execute their responsibilities.

Arch-Fab’s Operation Process

TURNOVER

Precon presents all relevant information to the Designer, Project Manager (PM), Assistant Project Manager (APM), and other imperative team members. The Project Manager reviews the project and prepares any important questions and documents the most important information to help each project be successful such as schedule, details, budget, and promises made to the client.

AFTER TURNOVER

The Project Manager with the Assistant Project Manager will send an introductory email to the most important members of the project team to clarify any remaining questions and get on the same page as the project team.

SUBMITTAL PROCESS

The PM and APM will then oversee the creation of the submittal package for the project. The assigned designer and project manager will determine the due dates of the submittal package for each release. Once all details are satisfactory, the submittal package is sent to the client for approval. Learn more about our detailed submittal process.

PRODUCTION RELEASE

Once the submittal package is approved by all parties, the PM will request a production release from our design team. The release includes all the parts and pieces required to create the final product for our fabrication team. This includes the dimensions of each material and fasteners and any detail imperative to the success of the product fabrication and finishing.

FABRICATING & FINISHING

Materials are pulled and assembled to the greatest extent possible and readied for the jobsite.

PACKING

The material management team will count, pack, wrap, and load all parts of the projects in crates and pallets. The project management team checks their work to confirm everything is accounted for before their transport to the next location – whether they ship to site or the installation team travels to the jobsite to install them.

Once billing is complete and the job work is punched and satisfactory, the work of the PM and APM is complete for a finished project.

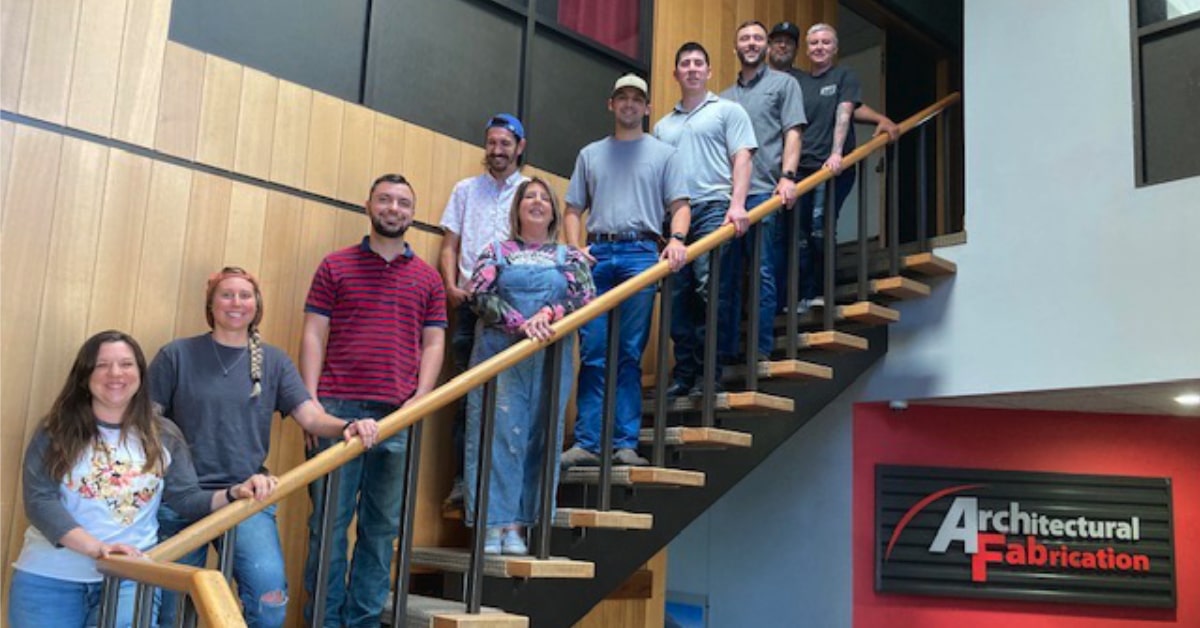

Arch-Fab’s Project Management Team